The 18th (2018) Yamazaki-Teiichi Prize Winner Semiconductor & Semiconductor Device

Development of high sensitivity InSb・InAs thin film Hall sensors and their applications

| Winner | ||

|---|---|---|

| Ichiro Shibasaki | ||

| History | ||

| Mar. 1971 | Completed the Doctoral Course in Department of Physics, Graduate School of Science, Tokyo University of Education | |

| Apr. 1971 | Assistant, Department of Physics, Faculty of Science, Tokyo University of Education | |

| Jan. 1974 | Entered Asahi Chemical Industry Co., Ltd. (now Asahi Kasei Corporation) | |

| Oct. 2003 | Group Fellow, Asahi Kasei Corporation | |

| Sep. 2006 | Retired from Group Fellow and assumed the post of Corporate Advisor, Asahi Kasei Corporation | |

| Sep. 2008 | Left Asahi Kasei Corporation | |

| Apr. 2009 | Specially Appointed Professor, Toyohashi University of Technology (Retired in March 2016) | |

| Scientific Advisor, The Noguchi Institute | ||

| Present | ||

Reason for award

In the 1970s, practical applications of semiconductor magnetic sensors were limited because of a

lack of miniaturization, high sensitivity, and good temperature properties. Shibasaki focused on thin

films of group Ⅲ-V compounds such as InSb and InAs with acceptable Hall effect properties. He

studied their electron transport properties and developed methods of fabricating monocrystalline and polycrystalline thin films and quantum wells. Furthermore, he established mass production technology. He was also a pioneer in developing ultra-thin, ultra-high sensitivity thin film Hall elements, namely, InSb and InAs poly and mono-crystalline thin film Hall elements as well as InAs quantum well Hall elements, and their practical utilization. The highly sensitive InSb thin film Hall elements were used first as magnetic sensors, they had 20 to 30 times higher magnetic field sensitivity than the other InSb Hall elements at the time, and their sensor signals had temperature dependences lower by one order of magnitude compared with the conventional ones. The elements were also very reliable because of the small resin package. Therefore, they were widely used as rotation detection sensors in Hall motors for VCR for home use, CPU

cooling fans for PCs, HDDs, and CD-ROMs and so forth. With the subsequent development of the InAs single crystal thin film Hall elements and the InAs quantum well Hall elements, the file of application expanded to include devices such as motors of air conditioners, contactless current sensors which are key devices for measuring electric current and electric-power in the electric power equipment and inverter controls and sensors for automobiles and electric-powered vehicles. Cumulative production has exceeds 30

billion pieces, and the list of applications is still expanding.

On the basis of these achievements, Dr. Shibasaki has been awarded the 18th Yamazaki-Teiichi Prize in Semiconductor and Semiconductor Devices.

Background of research and development

In the latter half of the 1970s, Japanese electronics manufacturers were concentrating their efforts on developing VCRs, PCs, and so forth. For the mechanical drives of these systems, it became necessary to develop compact DC brushless motors with very low noise, known as Hall motors, whose angular velocity could be finely controlled electrically. The Hall motors needed very small Hall elements as magnetic sensors to detect the angular position and velocity of the permanent magnet rotor. However, the elements available at the time for measuring the magnetic field were handmade and could not be mass produced. Furthermore, their sensitivities were too low to be used in a Hall motor. At the time, the semiconductor research was heavily focused on Si LSIs and electronic devices made from GaAs. There was no research on Hall elements for Hall motor use. This was a big problem facing the new motor development. Meanwhile, in the mid-1970s, the oil shock had forced Japanese chemical companies into other fields of business. In particular, Asahi Chemical Industry Co. decided to start development of Hall elements without any experience in semiconductor research.

Achievements

Dr. Shibasaki joined Asahi Chemical Industry Co., Ltd. (now Asahi Kasei Corporation) in 1974 and worked in its Hall elements research group. Although he had specialized in physics during university, he threw all his energy into the research, looking at the high electron mobility of narrow-gap group Ⅲ-V compounds such as InSb and InAs, and the potential of Hall elements. He exercised his ingenuity in the research and development of vacuum deposition and molecular beam epitaxy (MBE) technologies, whose use in industry was being questioned at the time.

He pioneered industrial mass-production technology for polycrystalline and monocrystalline thin films, and as well as quantum wells made from InSb and InAs. He also investigated the electron transport properties of the thin films under a magnetic field and applied his findings to the fabrication of Hall elements. Eventually, he developed high-sensitivity InSb thin-film Hall elements,

Si-doped InAs monocrystalline thin-film Hall elements, and InAs quantum-well Hall elements.

These reliable Hall elements in a very small resin package had the highest magnetic field sensitivity attained at the time. Thus, they were considered highly practical magnetic sensors.

In the development of the first high sensitivity InSb thin film Hall elements, he established a unique vacuum deposition method to fabricate InSb thin films that exhibit high Hall effect where he found a key operation method to control and achieve a five-order vapor pressure difference between sources of In and Sb.

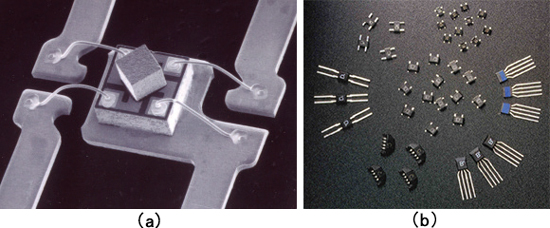

He also found a new Hall element structure that increased the sensitivity to magnetic fields by several times, in which a 0.8-μm-thick InSb thin-film Hall element was sandwiched between ferrite substrate and a very small ferrite chip, as shown in Fig. 1(a). The developed Hall elements had 20 to 30 times higher detection sensitivity than other InSb Hall elements at the time and were the world’s first such elements with a high input resistance (350Ω). These elements could be driven at a constant voltage of 1 V, and the temperature dependence of the Hall voltage which is the signal in

the magnetic field detection was reduced by about one order of magnitude compared with

conventional ones. They were considered highly practical small magnetic sensors. Figure 1 shows photographs of these high-sensitivity InSb thin-film Hall elements, including a bare Hall element without a package (a) and commercially available Hall elements (b).

Fig. 1 Photograph of high-sensitivity InSb thin-film Hall element

(a)Hall element before packaging, (b)commercially available products

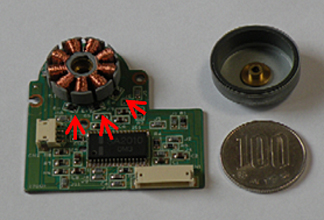

Immediately after they were developed, the Hall elements were used in small Hall motors for precise electrical control of the angular rate, and mass production commenced. In particular, the Hall elements made a great contribution to the development, popularization, and advancement of VCRs and PCs. In addition, they opened up a new field of electronic control of motor technology. The photograph in Figure 2 is a Hall motor of a CD-ROM for a PC. The motor has three Hall elements.

Fig. 2 Hall motor in a CD-ROM drive using three high-sensitivity InSb thin-film Hall elements (red arrows)

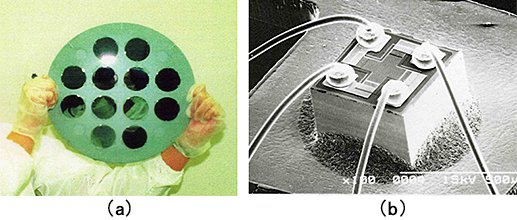

Next, by leveraging his experience and ingenuity in vacuum deposition technology, Shibasaki focused his research to molecular beam epitaxy (MBE) growth of thin films and developed a mass production MBE system with a large growth area that could produce InAs monocrystalline thin films and quantum wells on twelve 2-in. diameter GaAs substrates in one operation.

By using those MBE grown monocrystalline thin films, Si-doped InAs monocrystalline(single-crystalline) thin-film Hall elements were developed and mass produced.

Fig. 3 (a)0.5-µm-thick InAs monocrystalline thin films grown on twelve GaAs substrates, (b)a InAs single-crystalline thin-film Hall element fabricated on a GaAs single-crystal substrate.

Furthermore, by using AlGaAsSb insulating layers lattice matched to InAs as a potential barrier,

InAs quantum wells with the structure

GaAs (10 nm) ⁄ AlGaAsSb (50 nm) ⁄ InAs (50 nm: quantum well) ⁄ AlGaAsSb (500 nm) ⁄ GaAs (substrate)

were grown on GaAs substrate by MBE for use as Hall elements. The result was the world's first 50 nm-thick InAs quantum-well Hall elements, which were put to practical use.

The magnetic field sensitivity of these MBE produced Hall elements was very high, and their

power consumption was very small. The InAs Hall elements produced by the MBE method have

very small temperature dependences and high reliability and can be stably driven over a wide range of temperatures, from −40℃ to more than 100℃. They are widely used today as contactless sensors, magnetic sensors of contactless current sensors, and so on. Their applications include those in which InSb thin-film Hall elements are not suited. Figure 4 shows an example of a current sensor

with a linear hybrid Hall IC in which an InAs quantum-well Hall element, as a magnetic sensor, is packaged together with a Si IC linear amplifier. This current sensor is mainly used in inverters for

driving power motors.

Fig. 4 Current sensor using InAs quantum well Hall elements as magnetic sensors

The Hall motor is a power-saving motor by the variable angular rate control. The rate control is why this kind of motor has been used to reduce the power consumption of many electrical systems.

These motors are currently being used to drive air conditioners and various home appliances.

A contactless current sensor using magnetic-sensing Hall elements is a key device in invertor drive motors and for measuring electric power and current in the power electric field. Hall elements have recently been used as contactless switches and as automotive sensors including electric vehicles.

The estimated market share of thin-film Hall elements is 70%, and cumulative production since their advent has exceeded 30 billion units. The number of applications is increasing.

Meaning of the achievements

The significance of Dr. Shibasaki’s achievements lies in the establishment of industrial technology for mass-producing InSb or InAs thin films and quantum wells and the development of high-magnetic-field-sensitivity InSb and InAs thin-film Hall elements required by industry at the time irrespective of common knowledge or fashion.

The prizewinner has made the final 20 years of the 20th century and the first decades of the 21st century an era of electronically controlled motors. In this era, the ideal power source, namely the Hall motor with its ability to control the angular rate freely and precisely, became readily available to all of society. In addition, he made contactless sensors utilizing magnetism readily available to us all. Thus, he has greatly contributed to the electronics and information technology industries.

He has had a number of publications highlighting the academic achievements in his research and development and has greatly contributed to the development of relevant academic fields.